In plastic processing, ‘sheet processing’ refers to the handiwork of craftsmen, including heat treatment bending, welding, and adhesion.

Sheet processing is a process that requires a high level of aesthetics. Therefore, a high level of creativity is required. Kubopura’s sheet processing is carefully finished by technicians who excel in creativity and technique.

We have also developed techniques such as the production of R-grooves (water tanks with rounded corners) using a single sheet. We also handle the bending of polycarbonate

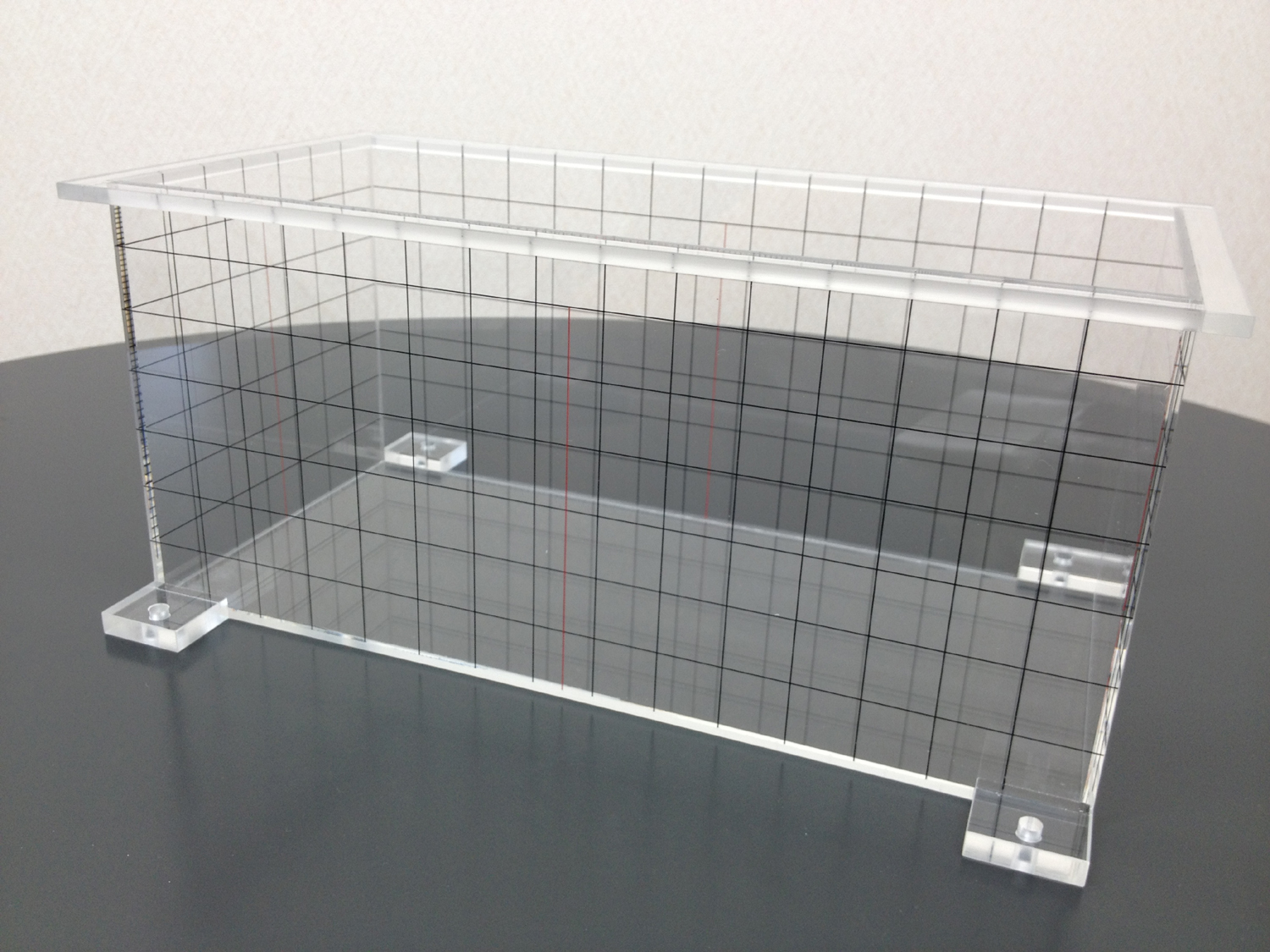

Adhesive and Welding Processing

Plastic bonding and welding is a technique, as the name suggests, that involves adhering resins together with adhesive or welding them using a welding rod melted by heat. As it is a manual process, the skills and sensibilities of the artisan greatly influence the outcome

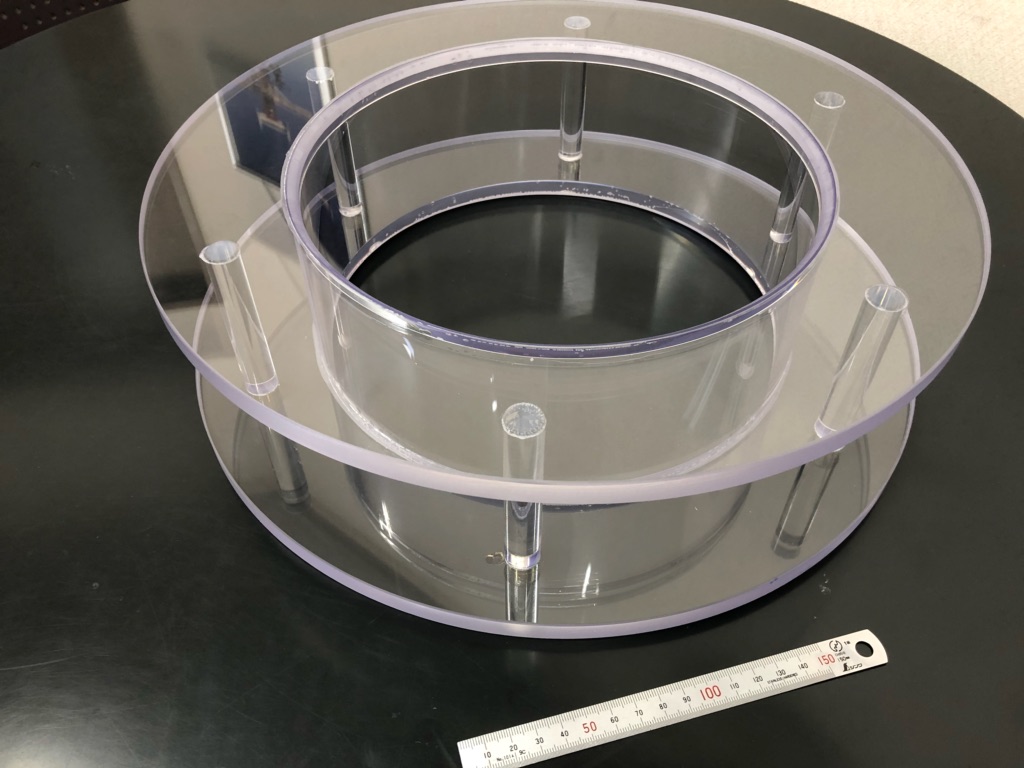

Heat Processing and Bending Processing

Bending processing involves creating smooth curves, carving grooves, and bending at angles.

After softening materials such as polycarbonate and PVC in an electric furnace, they can be bent using a mold to create cylindrical and conical shapes

Polycarbonate Processing (Bending, Welding, Adhesive, Assembly)

In recent years, there has been a significant increase in the demand for polycarbonate processing. One of the attractions of polycarbonate, a type of transparent plastic, is its heat resistance temperature of approximately 120°C