UNILATE® Machining

UNILATE® is a laminated sheet material manufactured by compounding polyethylene terephthalate (PET resin) with short glass fibers and inorganic fillers, followed by extrusion molding and hot lamination pressing.

Compared with thermoplastic resin sheets such as nylon and polyacetal, UNILATE® offers superior heat resistance, electrical properties, mechanical strength, and dimensional stability.

In electrical insulation applications, it provides significantly improved water absorption characteristics, electrical performance, and machinability compared with thermosetting resin laminated sheets.

UNILATE® delivers outstanding performance compared to competing materials, particularly excelling in fundamental properties such as electrical insulation, low water absorption, rigidity, and heat resistance.

Properties of UNILATE®

Heat Resistance Temperature: 120°C

Specific Gravity: 1.63

Flammability: Self-extinguishing (UL 94 HB)

Chemical Resistance: [Acid Resistance: Good] [Alkali Resistance: Fair] [Solvent Resistance: Good]

Advantages: Electrical insulation, low water absorption, rigidity, heat resistance

Disadvantages: Poor alkali resistance, wear resistance

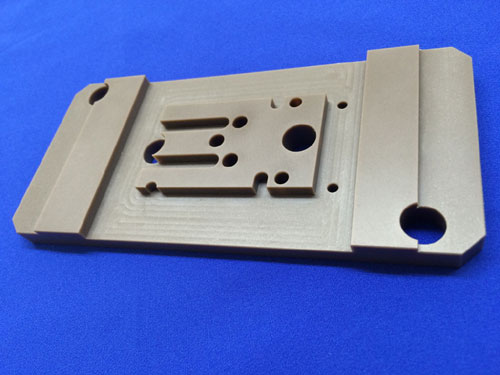

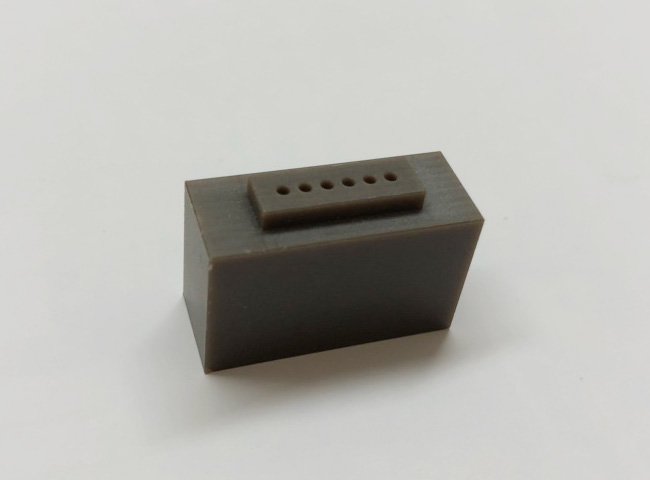

UNILATE® Machining Product Examples

UNILATE® is proposed as an alternative to paper-based phenolic laminate.

Compared with paper phenolic materials, UNILATE® offers significantly lower water absorption, providing greater advantages for end users.

UNILATE® was proposed as an alternative due to insufficient dimensional stability with MC nylon.

By combining the superior properties of UNILATE® with our precision machining capabilities, we were able to deliver high-quality products that fully satisfied our customers.

Physical Properties of UNILATE®

Manufacturer (UNITIKA | UNILATE®)Please refer to this page for details.